Solar technology

System for capacitive disassembly detection on solar plants

From the first sketch to series production - we turn your visions into reality.

Our field

Today, highly complex electronic products place very high demands on the production of such assemblies and systems. Therefore, the technical and economic implementation is always a challenge that we are happy to meet. The respective individual solution is developed in cooperation with you.

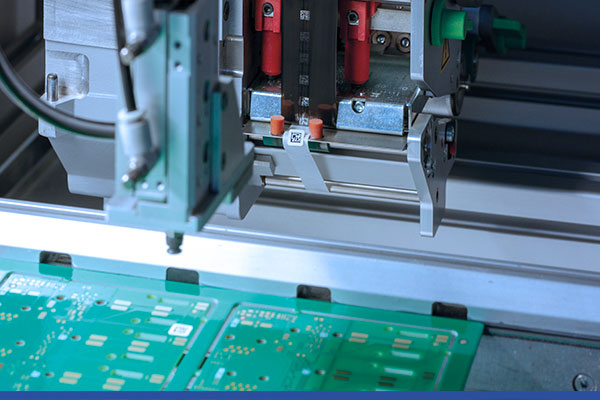

Whether prototype, small or large series - together with you we will find a solution for almost any technical and economic requirement. Over 50 years of experience, state-of-the-art technical equipment and systems guarantee perfect interaction, which has made us a sought-after partner.

Your contact persons

Andreas Heß

Tel.: 034771-5158

E-Mail: a.hess@vtq.de

Mandy Meyer

Tel.: 034771-511058

E-Mail: m.meyer@vtq.de

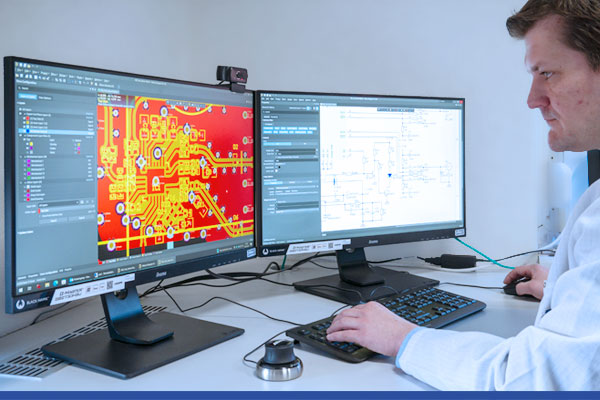

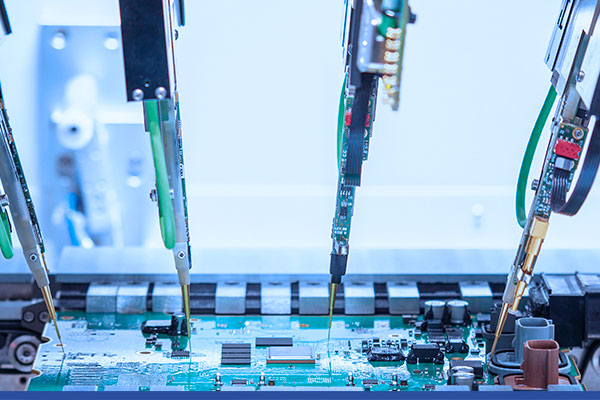

Precision meets efficiency

We are specialized in assembling electronic components in THT and SMD technology. Thanks to our state-of-the-art equipment, we are able to process every order quickly, efficiently and precisely. Our quality standards guarantee a professional result, so that you can look forward to a first-class product.

Innovation through Technology

We accompany you already during the development of your products and offer you a very extensive service with a very high vertical range of manufacture. From international purchasing of components, manufacturing of assemblies, assembly to the complete device, logistics with shipping to the end customer to the necessary after-sales service, we can act as your sole contact.